Resource Treatment of Black Liquor from Papermaking by Spray Drying

Since most of the raw materials for pulping in China are non wood fiber raw materials (accounting for more than 50%), alkali and acid recovery methods are used for the treatment of black liquor in most paper mills. However, due to the poor water filtration performance of grass pulp, many miscellaneous cells in black liquor, high viscosity and high silicon content of black liquor, the actual operation effect of alkali recovery method is poor, the average alkali recovery rate is only about 60%, low thermal efficiency, high operation cost and difficult management. Therefore, it is difficult to completely solve the problem of black liquor pollution in straw pulp plant. On the basis of research and development of spray drying and evaporation concentration for many years, and combined with the design and operation experience of introducing a single system for evaporation and concentration of black liquor in foreign countries, our company has proposed and implemented the zero pollution discharge process of black liquor treatment.

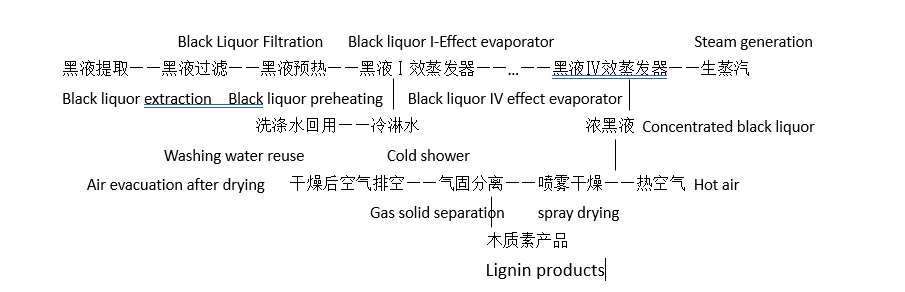

Condensed water and concentrated black liquor come out from evaporator, condensate can be used as washing water, while concentrated black liquor enters spray drying. During the spray drying process, the amount of dust discharged from the drying system is less than 100~150 mg/ m3, which can meet the national emission standards. No waste liquid is discharged, and lignin products are obtained at the same time. The whole process of black liquor treatment is not difficult to find, and there is no waste gas and liquid waste discharge in the whole process, so as to achieve the purpose of zero pollution discharge of black liquor treatment. Paper making black liquor is made into lignin products for comprehensive utilization. It is widely used in concrete water reducer, coal water slurry dispersant, asphalt emulsifier, ceramics, oil well exploitation additives, etc., so as to eliminate the damage to the ecological environment, create an environment-friendly, natural and harmonious development road, and truly realize the unity of economic benefits, environmental benefits and social benefits.

Zero discharge process flow of extraction black liquor

1. Material: papermaking black liquor and red liquor

2. Air inlet temperature: 280 ℃ ~ 430 ℃

3. Air outlet temperature: 110 ℃

4. Dry powder output: 1000 kg / H ~ 4000kg / h

5. Solid content: 40% ~ 50%

6. Heat source: direct fired coal-fired hot blast stove with settling chamber, superheated steam, etc. (can be replaced according to customer conditions)

7. Atomization mode: high speed centrifugal atomizer is adopted

8. Heating method: direct coal-fired hot blast stove (with four-stage settling chamber to effectively prevent Mars from entering)

9. Material recovery: primary cyclone dust removal and secondary wet water washing dust removal are adopted, with a recovery rate of 99.8%, which is in line with the national standard Emission standards.

10. Receiving: centralized receiving is adopted. The bottom of the tower and the powder discharged from the cyclone dust collector are uniformly sent to the by the air supply system Packaging shall be carried out in the warehouse of the designated packaging workshop.

11. Electrical control: PLC program control is adopted. (automatic control of air inlet temperature, air outlet temperature, oil temperature and oil pressure alarm of atomizer and negative pressure display in tower)