Flue Gas Desulfurization

Brief Introduction of Semi-dry Desulfurization Technology for Sintering Furnace Flue Gas in Iron and Steel Industry

In 1986, Wuxi Linzhou Drying Equipment Co., Ltd, using large-scale spray drying technology, jointly with Southwest Electric Power Design Institute, Nanjing Institute of Forestry & Chemical Industry, Chongqing University and other scientific research institutions, undertook the special topic of "Research on high sulfur coal rotary spray semi-dry desulfurization technology" in the national "The seventh five-year plan" environmental protection science and technology research project.After several years of research, a complete set of Chinese-style equipment has been set up in Sichuan Baima Power Plant and the predetermined technical indexes have been fully completed, making this desulfurization technology research a big step towards industrial application.The subject passed the technical appraisal organized by the State Department of Energy in 1990 and won the second prize of the State Scientific Research Progress Award.

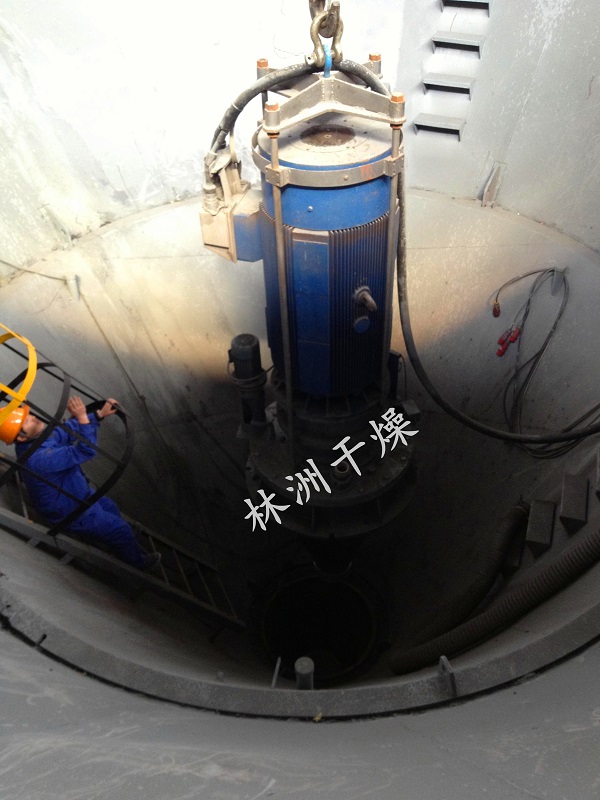

In 1998, semi-dry flue gas desulfurization technology was listed as one of the contents of localization. Wuxi linzhou drying equipment co., ltd, jointly with southwest electric power design institute, Nanjing institute of forestry and chemical industry, Chongqing university and other scientific research institutions, undertook the project of "industrial test and research on semi-dry flue gas desulfurization equipment". the contract number was SPKJ005-02 and the project code number was j-16ikj98.The treated flue gas volume is 400,000 Nm3/h.Wuxi linzhou drying equipment co., ltd. is mainly responsible for the main components of the project: high-speed centrifugal atomizing unit with 45 tons of liquid spray per hour.After successful trial production, it was put into operation in Guizhou Chuanheng Chemical Co., Ltd. in 2005. The auxiliary motor has a power of 312KW and a maximum spray volume of 50 t/h. The equipment operates at full capacity all year round with a daily dry powder production of 600 tons.Up to now, many sets of units have been put into operation in the field of large-scale chemical industry. The units operate continuously throughout the year with stable performance and reliable equipment stability.

While the 45T/h centrifugal atomizing unit is being developed and produced, the research and development team has also carried out research on the structural design of the semi-dry desulfurization tower, the flow field analysis in the desulfurization tower and the particle field. The research and development team has also been organized to measure and analyze the equipment imported from Denmark's NIRO Company, and has introduced the relevant software technologies for the design of the hot air distributor and desulfurization tower of NIRO Company.He has successively participated in the bidding of 125MW units in Zhejiang Qian Qing Power Plant and 100MW units in Yunnan Xiaolongtan Power Plant for semi-dry desulfurization projects. Judging from the bidding situation, he has great advantages in price, but he has been rejected due to lack of commercial performance. Therefore, for many years, most of the semi-dry desulfurization processes used in domestic power plants are imported equipment from abroad.

In recent years, with the improvement of national environmental protection requirements, the flue gas desulfurization of sintering furnace in steel mills, as a key national control target after the flue gas desulfurization of power plants, has accounted for about 11% of the national emissions of SO2 and other atmospheric pollutants in the steel industry, ranking second only to the power industry.Among them, the emissions of dust, SO2, CO2 and other pollutants generated in the sintering process account for 40% ~ 60% of the annual emissions of the iron and steel industry.Therefore, it is of great significance for the sustainable development of the iron and steel industry and the improvement of the ecological environment to control the emission of pollutants from sintering flue gas and to carry out the technological transformation of sintering flue gas desulfurization.

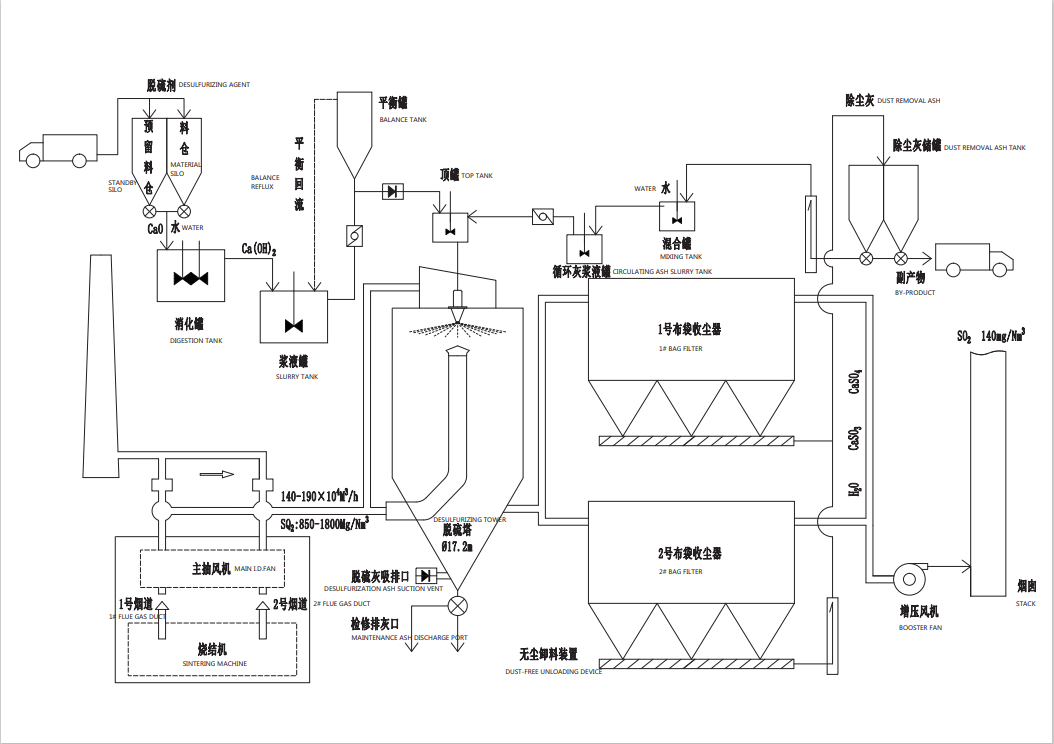

Referring to more than 10 users of sintering flue gas desulfurization process and dozens of desulfurization process design units such as Shougang, Jinan, Baosteel and Tangshan, spray drying semi-dry sintering flue gas desulfurization process is widely used. The spray drying semi-dry desulfurization process has the characteristics of mature technology, simple process flow, high system reliability and the like. The desulfurization rate can reach more than 85%, SO2 emission concentration after desulfurization ≤100mg/Nm3, and dust emission concentration ≤50mg/Nm3..The process has a certain application range (8%) in the United States and some western European countries.Desulfurized ash can be used as cement additive, mortar additive, gypsum preparation, etc.

In recent years, Wuxi Linzhou Drying Equipment Co., Ltd. has jointly launched adaptive development research on flue gas desulfurization of sintering machines in steel mills with Nanjing Forest Products Chemical Research Institute, Jinan Iron and Steel Group, Dalian University of technology and other institutions:

In conjunction with Dalian University of Technology, a pilot plant for flue gas desulfurization in sintering furnace was established in Chongqing Iron and Steel Group.

The desulfurization tower design of the 320m2 sintering machine desulfurization project of Jinan iron and steel group co., ltd. and the domestic test of the domestic 45-ton atomizing unit have achieved a good effect of switching between domestic equipment and imported equipment.