Compressed Air Transmission Centrifugal Atomizer

High-speed centrifugal atomizer is one of the key equipment of spray drying. Its atomization ability and atomization performance determine the final quality of the dried product. Therefore, research and manufacturing of high-speed centrifugal atomizer is always our focus.

Our company is the earliest domestic company to develop and produce dryer atomizers.In the early days, it was the only atomizer manufacturer in China with many national patents. Especially 45t/h and 50t/h high speed centrifugal atomizers, our company was the only manufacturer in China

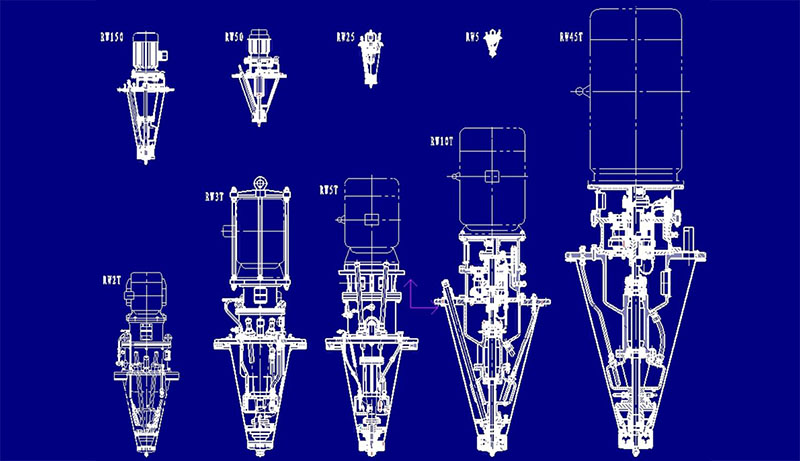

In the early 1980s in China, we first started to develop small-scale high-speed centrifugal spray dryers for laboratory use. Until now, we have developed and maturely applied high-speed centrifugal atomizers for key equipment of experimental and industrial spray dryers. A series of products with a total of 9 specifications has been formed, with a processing capacity from 5 kg / hour to 45 tons / hour. The diagram is as follows:

The atomizer is a component in the spray drying device that enables the atomizing medium to obtain high energy and high speed and is also a key component that plays an important role in the atomization efficiency and the stability of the atomization process. The motor drives the large gear through the coupling, the large gear meshes with the small gear on the rotating shaft, and the gear shaft after the first speed increase drives the second gear to achieve high-speed rotation of the atomizing disk. When the material liquid enters the feeding tube of the centrifugal atomizer and flows uniformly into the high-speed rotating spray plate through the material liquid distribution plate, the material liquid is sprayed into extremely small atomized droplets, which greatly increases the surface area of the material liquid. When the hot air in the drying room comes into contact, the moisture evaporates quickly and can be dried into a finished product in a very short time.

(1) When the material feed rate fluctuates, the gear drive has a constant rotating speed and high mechanical efficiency;

(2) The long cantilever structure is adopted to realize the "automatic centering" effect when the main shaft is running and reduce the vibration of the main shaft and the atomizing disc.

(3) Set floating bearings to support the flexible shaft at three fulcrums so that the shaft system can quickly cross the critical speed.

(4) Reasonably arrange the fixed support position and arrange the fixed support position at the node position to reduce the vibration load of the shafting.

(5) The rotating speed can be adjusted steplessly, and the best rotating speed can be selected according to the characteristics of the dried materials.

(6) High-speed motor is adopted to directly drive the spray disc, thus saving mechanical transmission structure, having small vibration, uniform spray and low noise. The power is self-regulated with the load, with remarkable energy saving, low temperature rises and stable performance.

(7) Compact structure, small volume, light weight, easy for operation, cleaning and maintenance.

(8) The composite electric spray head adopts water cooling and air cooling at the same time, and selects grease lubrication and oil lubrication as required, which is more suitable for working in high-temperature environment, and has the functions of water cut-off, gas cut-off, overcurrent, overtemperature alarm, etc. at the same time, the performance is more stable.

(9) The magnetic suspension nozzle adopts magnetic suspension bearing instead of rolling bearing, which has no contact, friction and vibration, more uniform fog droplets and long service life.

High-speed centrifugal atomization

Two-fluid atomization

Pressure atomization

Suitable for atomization of various materials with low viscosity in industrial production and conditions such as harsh working environment, large treatment capacity, easy scaling of materials, etc. Widely used in chemical industry, medicine, food, building materials and other fields. Can produce uniform material spray within a larger feed rate variation range

|

Model |

Spray amount (kg/h) |

Model |

Spray amount (kg/h) |

|

RW5 |

5 |

RW3T |

3000-8000 |

|

RW25 |

25 |

RW10T |

10000-30000 |

|

RW50 |

50 |

RW45T |

45000-50000 |

|

RW150 |

100-500 |

|

|

|

RW2TA |

2000 |

|

We have a complete spare parts warehouse and sufficient service and maintenance personnel to arrive at the customer's site for maintenance within 48 hours in China.

The large-scale high-speed centrifugal atomizer with a capacity of more than 45 t/h developed by our company and together with several scientific research institutions has filled the gap in the research and development of large-scale atomizer in China.

45t/h high-speed Centrifugal atomizer appraisal meeting;

Dynamic Balance Detection;

Testing machine testing;

Testing site of high-speed Centrifugal atomizer.