Closed Cycle Organic Solvent Recovery Spray Drying Equipment

The closed-cycle organic solvent recovery spray dryer is dedicated to methanol, ethanol, isopropyl acetate, ethyl acetate, dichloromethane acetone, hexane and other organic solvents made of suspension or real solution, using inert nitrogen as the drying medium of the product closed-cycle spray drying process. The whole process product is oxidation-free, media can be recovered, nitrogen can be recycled, closed cycle system designed for organic solvent recovery, system explosion-proof control requirements are very high, system self-control performance is very high, GMP requirements are demanding. Commonly used for spray drying of new materials, precision ceramics, pharmaceuticals, battery materials, carbide (Wc.Fe) powder.

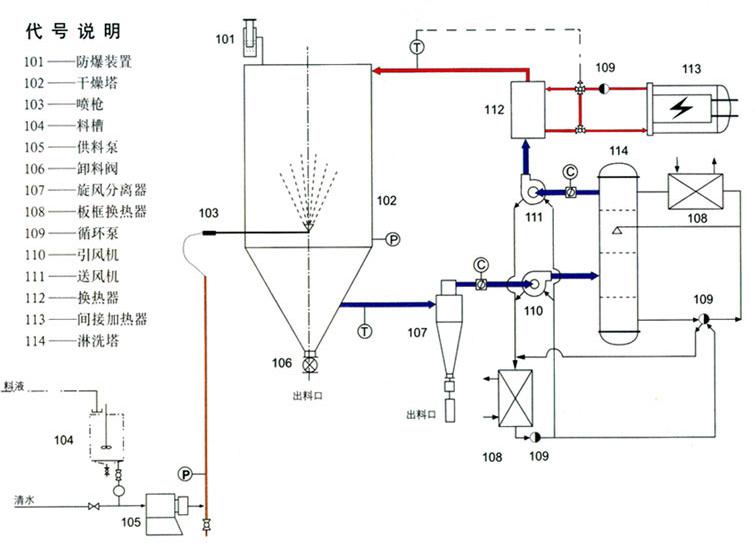

The closed spray drying system is also called a closed cycle spray drying system. It is characterized by the system forming a closed circulation loop, and the heat carrier can be recycled. For volatiles which are organic chemical solvents, which are toxic or escaping, and which can cause harm to people and the environment, the drying of materials. The organic solvents or products contained in the liquid are oxidizable, flammable and explosive materials. The materials used in this process are not exposed to oxygen, so most of the heating medium uses inert gases (such as nitrogen, carbon dioxide, etc.). The exhaust gas discharged from the dryer, after the gas-solid separation, also needs to be recovered by the condenser to remove the solvent or remove the moisture, and then heated by the heater to enter the dryer for recycling. This type of dryer needs to add refrigeration equipment in the system, which requires higher operating costs and higher air-tightness requirements of the equipment. Atmospheric or micro-positive pressure is mainly used in the dryer to prevent air from entering the system.

The closed cycle spray drying equipment works in a closed environment. The drying medium is an inert gas (or nitrogen). It is suitable for the drying of toxic gas materials or materials that are prone to oxidation during the drying process. The system uses inert gas as the circulating gas, which has a protective effect on the dried materials. The circulating gas undergoes the process of loading and dehumidifying, and the medium can be reused. The nitrogen is heated by the heater and enters the drying tower. At the centrifugal nozzle, the powdery material atomized by the high-speed circulating atomizer is discharged from the bottom of the tower. The evaporated organic solvent gas under the pressure of the negative pressure of the fan, the dust trapped in the gas is passed through the cyclone separator and sprayed. After the dust removal from the shower tower, the saturated organic solvent gas is condensed into a liquid by the condenser and discharged from the condenser. The non-condensable gas medium is continuously heated and reused as a drying carrier in the system. The conventional ordinary centrifugal spray drying achieves the purpose of dehumidification through continuous air supply and exhaust. This is also a significant difference between the explosion-proof closed centrifugal spray drying equipment and ordinary centrifugal spray drying equipment; the inside of the drying system is under positive pressure To maintain a certain positive pressure value, if the internal pressure drops, the pressure is automatically controlled by the pressure transmitter to ensure the system pressure balance.

|

Sr. No. |

Client's Name |

Project Name |

|

1 |

Yangzhou Qifeng Nanomaterials Co. , Ltd. |

QZBR-50 Closed Cycle Lithium iron phosphate |

|

2 |

Jiangsu Ruihe New Material Co. , Ltd. |

QZBR-1500 Closed-cycle chloroform |

|

3 |

Ningxia Taiyixin Biotechnology Co. , Ltd. |

QZBP-600 Closed-cycle dichloromethane |

|

4 |

Beijing Scientific Instruments & Materials Corp. |

QZBR-10 Closed cycle.-acetone |

|

5 |

Zibo Guiyuan Taisheng Ceramic New Material Co. , Ltd. |

QZBP-50 Closed cycle.-ethanol |

|

6 |

Shouguang Fukang Pharmaceutical Co. , Ltd. |

QZBR-150 Closed- cycle dichloromethane |

|

7 |

Suzhou Tongxuan New Material Co. , Ltd. |

QZBR-100 Closed cycle.-ethanol |

|

8 |

Jiangsu Enhua Pharmaceutical |

QZBR-25 |

|

9 |

Yichang East Sunshine Changjiang Pharmaceutical

|

QZBR-25 Closed cycle.-ethanol |

|

10 |

Hubei Jinghong Biotechnology Co. , Ltd.

|

QZBR-600 Closed- cycle dichloromethane |

|

11 |

Guojia Xincai Hubei Environmental Protection Gel Industrial Park Co. , Ltd.

|

QZBR-100 Closed cycle-hexamethyldisilane |

|

12 |

Ruyuan Dongyangguang Pharmaceutical Co. , Ltd.

|

QZBR-25 Closed cycle.-ethanol |

|

13 |

Zhejiang Parker New Material Co. , Ltd.

|

QZBP-250 DMAC Closed cycle-sulfolane DMAC |

|

14 |

Yangmei group Shanxi Yangzhongxin Material Co. , Ltd. |

QZBR-900 Closed cycle-hexamethyldisilane |